How to fit steel braided brake lines to your Aprilia RS125

Fitting braided brake hoses will not give you greater stopping power, but it will give improved feel which is crucial to effective braking. This guide describes how to bleed the front brake. The process is the same for the rear brake, but bleeding is easier and can generally be done without removing the calliper.

Install the steel braided hose and bleed your brakes

- Empty the line by bleeding the brake.

- Connect hose to the nipple and loosen

- Pump the brake and it should eject fluid, which you can collect in your container.

- Keep the brake attached to the bike while you do this.

- Once the reservoir is empty, stick a clean rag in, soak up remains and prevent intake of dust.

- Loosen the master cylinder banjo bolt (beneath the banjo bolt there is a small ball bearing, be careful not to lose it).

- Use a rag to mop up any drips.

- Take the loose end of the hose, place it into your container and then place the container as low as possible.

- Fluid should drain into the container.

- Disconnect the hose from the caliper once it has stopped.

- Remove the calliper from the fork but there will still be fluid in it so keep it upright.

- With the hole into which brake fluid flows carefully positioned over your jam jar, squeeze the pads apart and it will eject most of the remaining fluid into the container.

- Remove the pads from the calliper and clean it thouroughly.

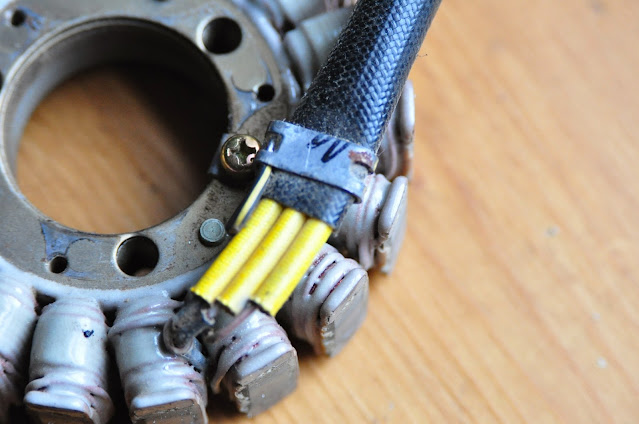

- Check that your new hose is of equal length to the rubber hose it will replace.

- Ensure it is properly routed.

- Take the new bolts from the box and reinstall the calliper

- Connect both ends of the hose and tighten up the new banjo bolts.

- Ensure that the small ball bearings have been replaced and that copper washers have been installed on either side of the new hose.

- Fill the reservoir half full with your new brake fluid and start bleeding the brake (this will take a while as the system needs to be primed with new fluid).

- Top up the reservoir as required.

- When you reach a point that you feel is acceptable take the bike out a few times and the leaver will get firmer with each use.

- On your return, flush a few more measures of fluid through the line and top up the reservoir (the instant you open the bleed valve it will go spongy, but close it up and it will get firm very quickly).

-------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------

hel brake line fitting instructions

Carefully remove the existing brake lines from the bike - avoid splashing the paint with brake fluid. Remove all the old washers and drain the system of brake fluid. Ensure all sealing surfaces are clean and in good condition. Fit the enclosed HEL brake line kit using the new copper washers supplied. Check the pitch of the new banjo bolts supplied in our kit with those being replaced on your bike. This is especially important with Suzuki Motorcycles as some models use both M10 x 1.00 and M10 x 1.25 pitch banjo bolts.

Installation

Experienced bike owners and mechanics will tell you that brake bleeding is easy. It is, but there's plenty of potential for error. Reading this guide will not turn you into an expert overnight. We have made every attempt to be correct and make this guide easy to read, but we cannot impart the gifts of skill, experience and common sense. If after reading this page you feel inclined to carry out bleeding to the braking system of a bike we will not accept responsibility for what happens next. You are responsible for your own actions and this information is offered as an introduction to bleeding.

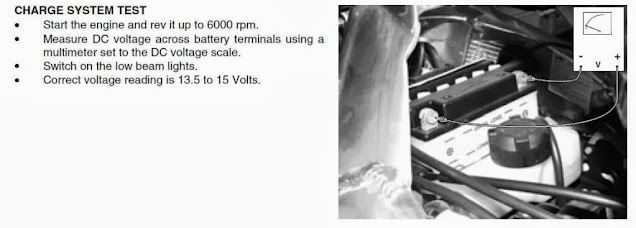

Even though it is possible to bleed bike brake systems on your own it's advisable and much easier if two people do it. You will need clean, fresh brake fluid which has been allowed to settle over night - do not shake the bottle before starting as this will put air bubbles into the fluid, a length of plastic tubing which fits tightly to the bleed nipple and a glass container so you can see the air being expelled from the system.

It's a good idea to cover areas around the master cylinder and the bleed nipples to protect from accidental spillage. The area around the master cylinder and the bleed nipples should be as clean as possible to avoid getting dirt into the system. Firstly you need to remove the old lines so attach the plastic tubing to one of the bleed nipples and open slightly so you can pump most of the old fluid out before you take the old hoses off. It's known for the bleed nipples to be seized in the calipers - mild steel nipples and alloy calipers will suffer electrolytic corrosion naturally and winter salt on the roads will only increase the effect. You may want to take the opportunity to replace the mild steel nipples with stainless steel ones.

Assuming that you have been able to undo the bleed nipples make sure the brake reservoir has plenty of fluid in it and then rest the cap back on top to stop fluid squirting out when you begin bleeding.

Priming (Filling) The System

If you have a twin disc system bleed one caliper at a time. Attach the tube to the bleed nipple and place the other end in the clean glass jar. Poor some clean brake fluid into the jar so the end of the tube is submerged so you don't pull air back in to the system. Then open the bleed nipple, squeeze and release the brake lever slowly to give the master cylinder enough time to suck in fresh fluid from the reservoir. Keep an eye on the master cylinder reservoir and make sure the fluid level does not fall below the minimum mark else you will start sucking air into the system. Fluid may be being pulled into the system from the jar and you may see the level drop - this is fine but again make sure the end of the tube is always immersed in fluid. It shouldn't take too many lever actions to fill the system. Tighten the bleed nipple when finished.

Bleeding The System

Open the bleed nipple slowly - you should only need half a turn and at the same time slowly and smoothly squeeze the brake lever in (or push the pedal). Hold the lever in and you should see air bubbles or fluid being expelled into the jar. Old brake fluid can be any colour from dirty white to brown or black. Movement of fluid and/or bubbles will continue for a second or two, close the nipple and then release the brake lever.

Check the fluid level in the reservoir and top up if necessary. Repeat this operation until no more bubbles appear and the fluid coming out is clear. Keep the master cylinder topped up.

If you have a twin system repeat this process with the other caliper (it's best to do the furthest away from the master cylinder first) if everything has gone okay you should now have a brake system with a good solid feel to it, the lever will travel a short distance and then a solid resistance will stop it moving any further.

If when you continue to apply pressure you get a slow movement or spongy feel to the lever it's a good sign that there is still air in the system. There are a number of possibilities not least that you didn't get all the air out of the system so you should start bleeding again. Tighten all parts to the correct torque setting and then check the system to see that the lines are not trapped on full lock, no fluid leaks from anywhere etc.

More information about this procedure can be found on our Brake Doctor brake and clutch line bleeding page

Troubleshooting

Not all calipers have their bleed nipples at the highest point on their anatomy. This means that if there is a small pocket of air trapped above the nipple it will be hard to remove (air always goes to the highest point of the area it is in) and make the system spongy. You can get around this by taking the caliper off and making sure the nipple is at the highest point but remember to put a spacer between the pads to stop the pistons popping out and making it easier to refit the caliper.

A similar problem occurs with some racing bikes which have steeply angled handle bars - the brake hose arches up above the master cylinder and a small pocket of air can get trapped here. Again you can rearrange the layout or you could inject brake fluid using a syringe very carefully and slowly in through the bleed nipple in the caliper bearing in mind that the fluid in the reservoir may overflow. Fitting a banjo bolt which includes a bleed nipple to the master cylinder and bleeding this first before the rest of the system is another way to fix this problem.

If you are unable to remove the sponginess no matter how carefully you bleed the system you may have a sealing problem which you will need to consult your local dealer about. The master cylinder is fed from the reservoir by a tiny hole and this hole easily gets blocked which is why cleanliness is so important when bleeding brakes. If you cannot bleed your brakes yourself make sure you talk to your local dealer and get them to do it for you. Don't be tempted to use any of the 'self bleed' gadgets unless you really have to. These products allow the nipple to be kept open as they include a non return valve to stop air re-entering the system. But the bleed nipple has a threaded end which screws into the caliper - air can be sucked into the caliper along this route if the nipple is loose in the threaded part of the caliper - it will only be a small amount but why do it in the first place as we are trying to remove air.

When you have successfully bled your brakes make sure both bleed nipples are done up tightly, all banjo bolts are done up tightly to the torque settings laid out below and top up the master cylinder reservoir with fresh brake fluid to the required level. Most standard reservoirs have an upper and lower limit shown on the reservoir itself. Do not overfill the reservoir as this can cause hydraulic locking of the system preventing the pistons in the caliper from fully retracting - this causes binding of the brakes.

Final Check

Re check the system visually before test riding - and we mean test riding. Just go forward a few feet slowly and apply the brakes then bring the bike back into the workshop to check that there is no fluid leaking from the system, everything is done up correctly and the brakes have a good solid feel to them. Do not ride your bike until you are certain you have bled the brakes correctly - If in doubt get your local dealer to bleed the system for you. Check that all end fittings are securely attached to each line. Check line(s) for clearance and that the kit has been installed without any kinks or twists in the system. Check that full suspension travel and steering lock are unaffected and that the hoses are not stretched or trapped in any way. Tighten the banjo bolts.

.jpg)

.jpg)

.jpg)

.png)